Gears are identified by many types and there are many specific technical words to describe their definition. The most common way to classify gears is by category type and by the orientation of axes.

Gears are classified into 3 categories: parallel axes gears, intersecting axes gears, and nonparallel and nonintersecting axes gears.

Spur gears and helical gears are parallel axes gears. Bevel gears are intersecting axes gears. Screw or crossed helical, worm gear and hypoid gears belong to the third category. Table 1.1 lists the gear types by axes orientation.

(1) Parallel Axes Gears

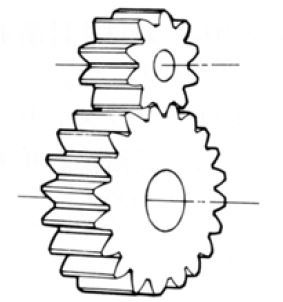

(1.1) Spur Gear

Spur Gear internal of Gear Motor

This is a cylindrical shaped gear, in which the teeth are parallel to the axis. It is the most commonly used gear with a wide range of applications and is the easiest to manufacture.

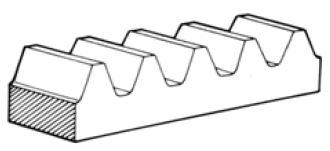

(1.2) Gear Rack

Gear Rack internal of Gear Motor

This is a linear shaped gear which can mesh with a spur gear with any number of teeth. The gear rack is a portion of a spur gear with an infinite radius.

(1.3) Internal Gear

Internal Gear internal of Gear Motor

This is a cylindrical shaped gear, but with the teeth inside the circular ring. It can mesh with a spur gear. Internal gears are often used in planetary gear systems.

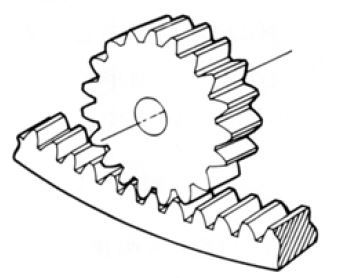

(1.4) Helical Gear

Helical Gear internal of Gear Motor

This is a cylindrical shaped gear with helicoid teeth. Helical gears can bear more load than spur gears, and work more quietly. They are widely used in industry. A disadvantage is the axial thrust force caused by the helix form.

(1.5) Helical Rack

Helical Rack internal of Gear Motor

This is a linear shaped gear that meshes with a helical gear. A Helical Rack can be regarded as a portion of a helical gear with infinite radius.

(1.6) Double Helical Gear

Double Helical Gear internal of Gear Motor

A gear with both left-hand and right-hand helical teeth. The double helical form balances the inherent thrust forces.

(2) Intersecting Axes

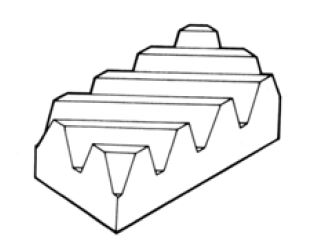

(2.1) Straight Bevel Gear

Straight Bevel Gear internal of Gear Motor

This is a gear in which the teeth have tapered conical elements that have the same direction as the pitch cone base line (generatrix). The straight bevel gear is both the simplest to produce and the most widely applied in the bevel gear family.

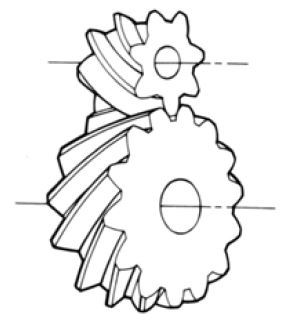

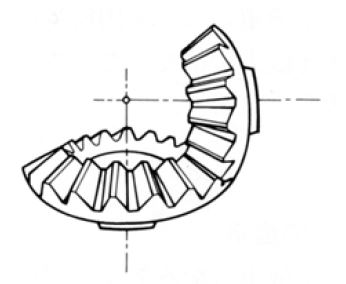

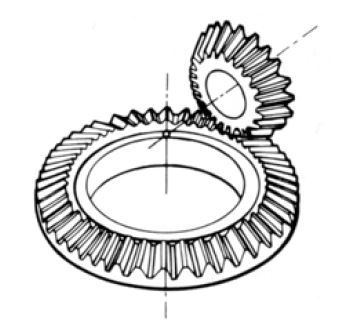

(2.2) Spiral Bevel Gear

Spiral Bevel Gear internal of Gear Motor

This is a bevel gear with a helical angle of spiral teeth. It is much more complex to manufacture, but offers higher strength and less noise.

(2.3) Zerol Bevel Gear

Zerol Bevel Gear internal of Gear Motor

This is a special type of spiral bevel gear, where the spiral angle is zero degree. It has the characteristics of both the straight and spiral bevel gears. The forces acting upon the tooth are the same as for a straight bevel gear.

(3) Nonparallel and Nonintersecting Axes Gears

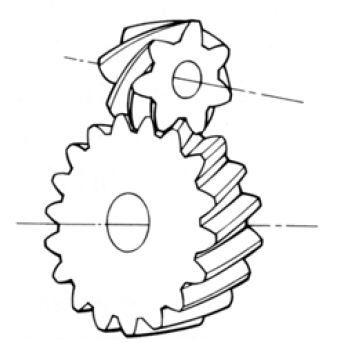

(3.1) Worm Gear Pair

Worm Gear Pair internal of Gear Motor

Worm gear pair is the name for a meshed worm and worm wheel. An outstanding feature is that it offers a very large gear ratio in a single mesh. It also provides quiet and smooth action. However, transmission efficiency is poor.

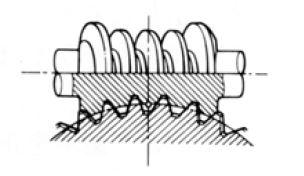

(3.2) Screw Gear (Crossed Helical Gear)

Screw Gear (Crossed Helical Gear) internal of Gear Motor

A pair of cylindrical gears used to drive non-parallel and nonintersecting shafts where the teeth of one or both members of the pair are of screw form. Screw gears are used in the combination of screw gear / screw gear, or screw gear / spur gear. Screw gears assure smooth, quiet operation. However, they are not suitable for transmission of high horsepower.

(4) Other Special Gears

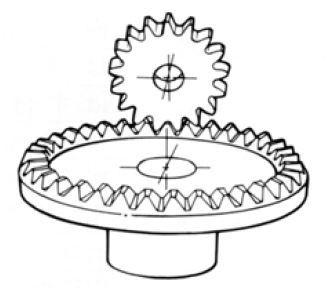

(4.1) Face Gear

Face Gear internal of Gear Motor

A pseudo bevel gear that is limited to 90° intersecting axes. The face gear is a circular disc with a ring of teeth cut in its side face; hence the name Face Gear.

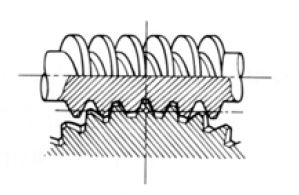

(4.2) Enveloping Gear Pair

Enveloping Gear Pair internal of Gear Motor

This worm set uses a special worm shape that partially envelops the worm gear as viewed in the direction of the worm gear axis. Its big advantage over the standard worm is much higher load capacity. However, the worm gear is very complicated to design and produce.

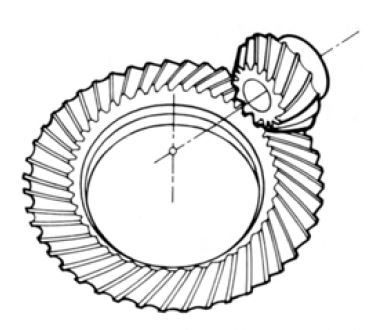

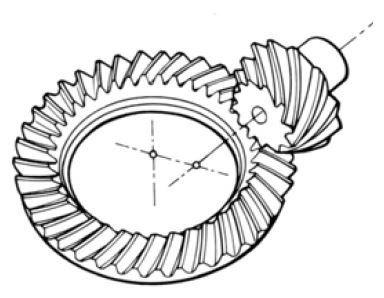

(4.3) Hypoid Gear

Hypoid Gear internal of Gear Motor

This gear is a slight deviation from a bevel gear that originated as a special development for the automobile industry. This permitted the drive to the rear axle to be nonintersecting, and thus allowed the auto body to be lowered. It looks very much like the spiral bevel gear. However, it is complicated to design and is the most difficult to produce on a bevel gear generator.

Buy the way, other more information or quotation of gear motor, please contact VEER Motor any time, email: sales@veermotor.com, or review official website: https://www.veermotor.com/