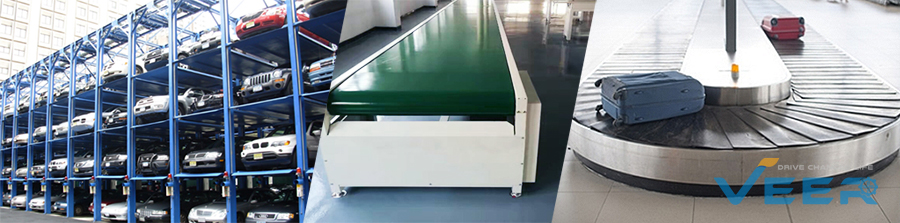

The advanced degree of robots in the current fashion is breathtaking. The close coordination of various parts ensures the accuracy of repeated movements and the reliability of the completion of technological tasks. It makes people wonder how their transmission system works? If someone knows the industrial controller knowledge, their will often be found gear motor applies in many fields, such as recreation equipment, carousel in airport or express company, stereo garage, and so on. All of the above are applied to such an indispensable power transmission equipment – Gear Motor.

Many applications of VEER gearmotor you need to know

The working principle of gear reduction motors

Gear Motor is a special transmission, which transfers motor power through gear set (or worm gear) reducer, the device greatly reduces the rotate speed, thus increasing the output torque of motor, then to meet the needs of mechanical equipment.

Classification of gear reduction motors

The most commonly used types of gear motors are coaxial helical gear motor, parallel helical gear motor, bevel gear type gear motor, worm gear motor

For more knowledges or quotation you want to know, please contact VEER Motor, email: sales@veermotor.com, or visit official website: VEER Gear Motor