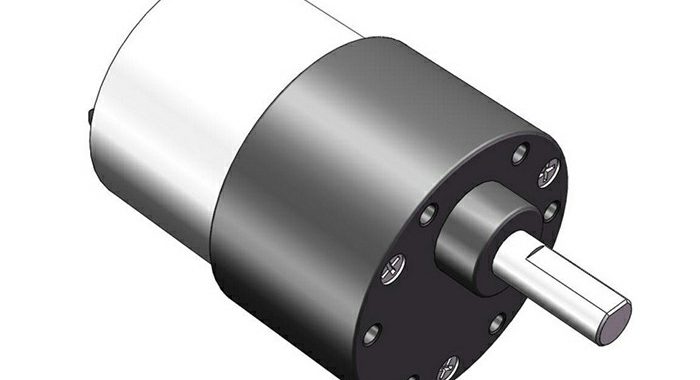

The new DC gear motor is manufactured from factory, which usually needs to pass the run-in period before using. The operation of gear motor during the run-in period has an important impact on the later use. Therefore, we should use the motor in the correct way during the run-in period to ensure that it can safely pass the run-in period.

The run-in period of DC gear motor is very important, so VEER Motor advises our customers carefully take care of your DC gear motor

- Choose lubricating oil reasonably, especially for dc motor with input power greater than 11KW, which load gear oil should be injected.

- At ordinary times, pay more attention to check the lubricating oil, hydraulic oil coolant, and keep the oil level and quality in good, pay attention to check the sealing of the whole gear motor. If too much oil is lost during inspection, which the reason should be analyzed. At the same time, the lubrication of each lubrication point should be strengthened. It is suggested to add grease to the lubrication point every week during the run-in period (except for special requirements).

- To keep the gear motor is clean, adjust the loose fastening parts of gear motor in time, to prevent the looseness of DC gear motor cause by the wear out of parts or causing the loss of parts.

- At the end of the run-in period, the motor should be maintained compulsive-check and adjusting, and pay attention to the replacement of lubricating oil.

In conclusion, the run-in period of DC gear motor is very important, so VEER Motor advises our customers carefully take care of your DC gear motor. Any maintaining questions of gear motor, just contact us freely.