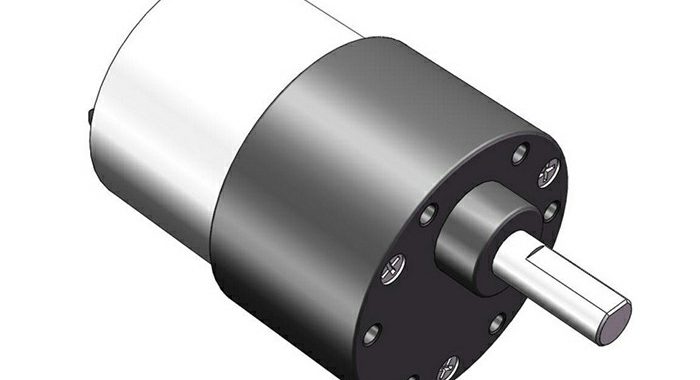

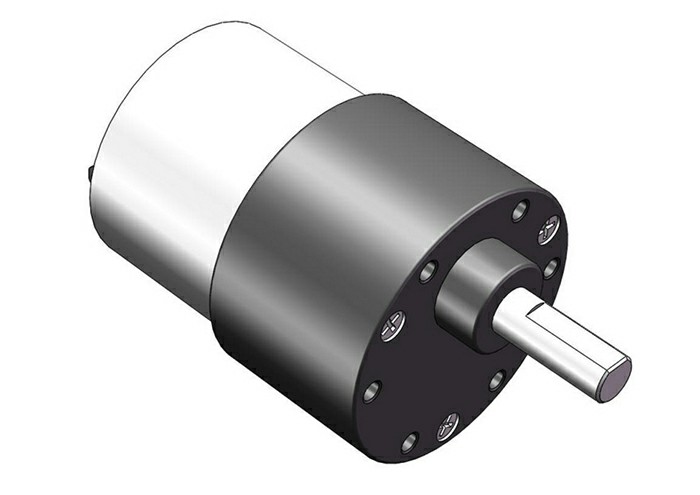

Geared DC motors can be defined as an extension of DC motor which already had its Insight details demystified. DC Motors convert electrical energy (voltage or power source) to mechanical energy (produce rotational motion). They run on direct current. The DC motor works on the principle of Lorentz force which states that when a wire carrying current is placed in a region having magnetic field, then the wire experiences a force. This Lorentz force provides a torque to the coil to rotate. A geared DC Motor has a gear assembly attached to the motor. The speed of motor is counted in terms of rotations of the shaft per minute and is termed as RPM. The gear assembly helps in increasing the torque and reducing the speed. Using the correct combination of gears in a gear motor, its speed can be reduced to any desirable figure. This concept where gears reduce the speed of the vehicle but increase its torque is known as gear reduction. This Insight will explore all the minor and major details that make the gear head and hence the working of geared DC motor.

VEER-Motor-is-Geared-Motors-Right-Angle-Gear-Motors-and-Gear-Reducers-manufacturers