In the reducer product series, gear reducer motor because of its small size, high transmission efficiency, wide selection of deceleration range, high precision, is widely used in servo, stepping, dc and other transmission systems. Their function is to ensure precision transmission premise, mainly used to reduce the speed and load/motor rotation to reduce the inertia ratio.

How to select a Gear Reducer Motor?

1. When choosing a gear reducer, it should be noted that:

Multiply the rated torque of your selected servo motor by the reduction ratio, and the value obtained is in principle less than the rated output torque of similar reducer provided by the product sample.

Also consider the drive motor, actual overload capacity and maximum operating torque, the maximum operating torque required is less than 2 times the rated output torque.

After the above conditions are met, please select the minimum reducer. Smaller reducers cost less. If there is not enough space for the motor reducer to connect in a straight line, you can also choose a Right Angle Gear Shaft Motors, which can make the torque 90 degrees.

2. Return clearance of gear reducer should also be considered

The smaller the return clearance, the higher the accuracy and the higher the cost. The user should select a speed reducer that meets the accuracy requirements.

3. Lateral/radial forces and average life should also be considered.

A reducer with large transverse/radial forces is very reliable for installation and use and is not likely to cause problems. Usually its average life is much longer than the life of the servo motor.

After meeting the above criteria, you can select the gearbox suitable for your motor according to the product catalog provided by the company in terms of installation size, axle diameter and input flange.

4. Finally, you must also consider the weight of the gear reducer motor.

A speed reducer is only allowed to match a motor of less than a certain weight. The motor is too heavy, which may damage the input flange of the reducer.

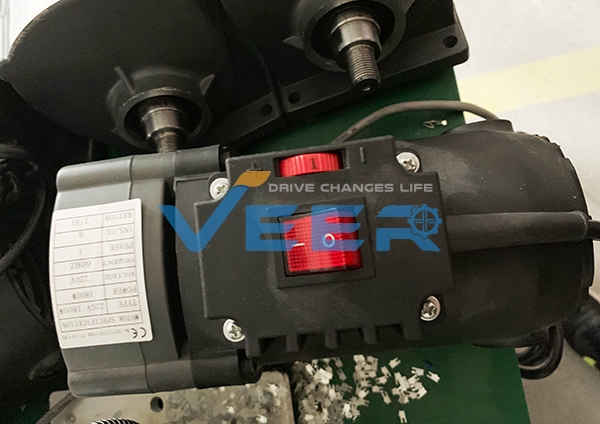

Veer Motor specializes in manufacturing, sales, and services of geared reducer motor, which wide product range includes helical geared motors, shaft-mounted geared motors, bevel-geared motors, worm geared motors, brushless motors, servo motors, brushless motor drives and servo drives.

Veer Motor adopts international standard to produce various types of reducer. Our wide product range includes helical geared motors, shaft-mounted geared motors, bevel-geared motors, worm geared motors, brushless motors, servo motors, brushless motor drives and servo drives. All manufacturers and distributors are welcome to purchase our gear reducer products. Please contact VEER Motor when you need to help, email to: sales@veermotor.com, or visit our official website: https://www.veermotor.com/