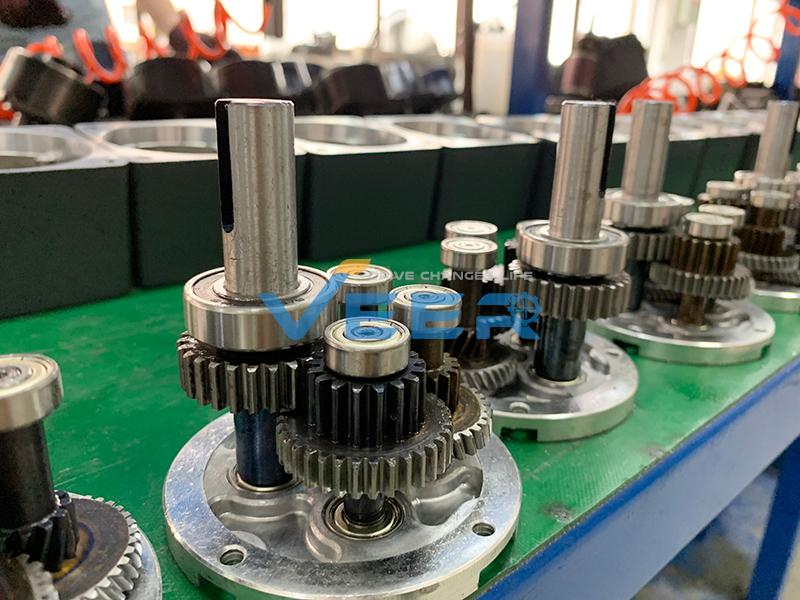

If you encounter the vibration from gear reduction motor? Please continue to read as VEER Motor.

- Whether Speed Reducer (Gearbox) Matches Electric Motor?

The gear reduction motor has both speed index and torque index, the rotate speed and torque are different even the powers of gear reduction motor are same, so as long as the gear motor is adopted by hard connection, there should be considered two indexes (rotate speed and torque). If the torque doesn’t meet the need torque from gear motor that the motor will vibrate or not rotate. Of course, in many times, in cases of rotate speed from high to low, the speed reducer (gearbox) can still running, but there is a defect, if gear motor is running for a long time, which will overload.

- Whether Gear Reduction Motor is overloaded or not?

In general situation, the gear reduction motor is used with other devices during running, the overloads are the needed, and each transmission equipment has their limit load index. So, the limit load index of gear motor should consider all members in whole, and environmental factor, etc. So, load determination is also an important factor to analyze vibration faults.