Many factories are very concerned about the service life of geared reducer motor when using. In fact, the service life of gear motor is not only related to the quality of the product itself, but also related to the use method and installation method of gear motor. In order to ensure longer service life of gear motor, and then reduce the failure rate, we should according to certain procedures to installation and using. VEER Motor company get so many customers’ response for how to install gear motor after getting VEER’s gear motor, we have made some tips as below:Many factories are very concerned about the service life of geared reducer motor when using. In fact, the service life of gear motor is not only related to the quality of the product itself, but also related to the use method and installation method of gear motor. In order to ensure longer service life of gear motor, and then reduce the failure rate, we should according to certain procedures to installation and using. VEER Motor company get so many customers’ response for how to install gear motor after getting VEER’s gear motor, we have made some tips as below:

What are the installation steps of geared motor?

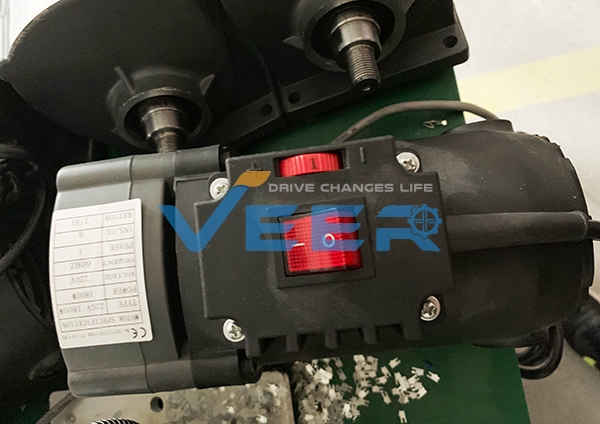

- Confirm whether the gear reducer motor is intact, and strictly check whether the size of geared reducer (gearbox) matches with the gear motor, which refers to sizes of bulge part, output shaft and groove, also include the tolerance of fit.

- Unscrew the screw on the dust proof hole outside of the flange, adjust the PCS system clamping ring, so that the side holes are aligned with the dust proof hole, and then insert the inner hexangular angle after tightening, remove the motor shaft key.

- Connect the motor with the reducer (gearbox) naturally, and ensure the concentricity of output shaft of the motor and the input shaft of the motor is same. And the outer flange is parallel. If the concentricity is not consistent, the motor shaft will be broken or the gear of the motor will be worn out.

- Check the veracity of the installation position of the reducer in order, and the reliability of the fasteners to ensure the all parts of gear motor rotate flexibly.

- Remove the screw plug of the air hole, replace it with an air plug, and lubricate of parts of gear motor.

5 Steps easily complete the installation of geared reducer motor

Proper installation is an important part to ensure the long service life of the gear motor. Therefore, we should install the gear motor in strict accordance with the above procedures. Of course, the regular maintenance in daily use is also important, so that to avoid damage of the gear motor during working. VEER Motor has over 10 years’ experience in gear motor production, who is a professional gear motor manufacturer. We served over 100 motor companies for OEM & ODM. And we have a professional after-sales team. If you have any question of gear motor need to resolve, just contact our technical team. Warmly welcome valuable suggestions from customers, which can make our gear motor products have more advantages in the market. Thank you!